|

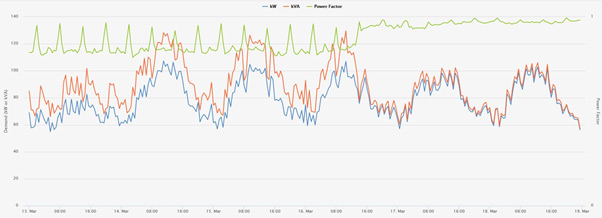

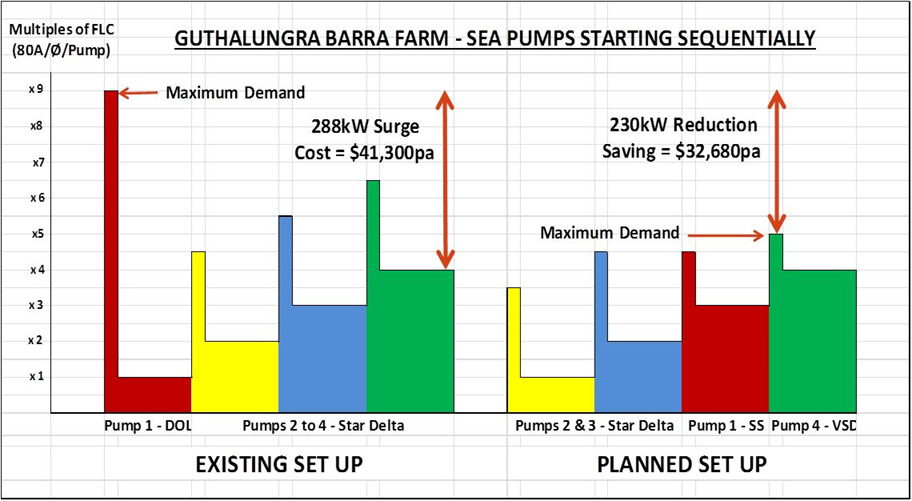

There are many ways to improve the energy efficiency of your plant and equipment, including the use of motor Soft Starters and Variable Speed Drives (VSDs), Power Factor Correction (PFC), and whole or part-site Energy Management Systems (EMS). Energy Efficiency measures are used not only to reduce costs, but also to increase the capacity of electrical supply and switchboards, and these measures are described in an energy efficiency audit. Think about the energy costs of major power-hungry components at your workplace, eg compressors, motors, pumps etc. The bar chart to the right shows the dramatic reduction in demand resulting in a saving of $32,680 pa when the sea pumps at GFB Fisheries barramundi fish farm were programmed to start sequentially instead of all at once. Such a simple thing - what a wonderful result! And the graph below clearly shows the moment 13 VSDs were switched on at Whitsunday Food Service (see project summary below), with the green line reaching its optimal performance in a dramatic manner, and the red line showing a valuable reduction in its peak.

|

|

Whitsunday Food Service |

|

|

In conjunction with Burdekin Air Conditioning & Electrical, VSDs were installed to 13 cold room and freezer compressors to reduce both peak demand and energy use. The VSDs were individually tweaked and programmed to achieve maximum reductions, confirmed by data logging over a period, with Ergon advising that they had recorded a network demand benefit of 29kVa, resulting in payment of over $10,000 in Ergon incentives. Operations Manager Mark Richards said“As the main food service distributor of the Whitsundays, we need to have ample storage space to meet the demands of our many and varying customer base. This storage space comes at a price, though, with 13 refrigeration units running around the clock. Alan, along with Burdekin Air Conditioning & Refrigeration, devised a plan to install VSD’s on all compressors throughout, and the end results were nothing short of amazing! We have seen a reduction to our peak KVA of over 30KVA with zero impact on refrigeration capabilities, as a result of these dramatic energy-saving solutions. I couldn’t recommend Alan and his team highly enough.” |

Coral Coast Barramundi |

|

|

Following a Level 3 Energy Audit at the fish farm, Tailored Energy Solutions have completed 3 separate, rapid-payback projects: One VSD and one soft-starter were used to achieve a 44% reduction in the peak demand of their 4 large sea pumps VSDs were fitted to the 2 sea canal lift pumps. Running these pumps at 75% of their rated speed has reduced energy consumption by ~200MWh/year. We sized and installed a 200kVAr Power Factor Correction unit to the Main Switchboard of the Fish Production Tanks, improving Power Factor in this area from 0.75 to over 0.98, which highlight our capabilities in providing energy saving solutions. General Manager Justin Forrester said “Alan Day has been advising us for over 2 years now. We are confident that he has our best interests at heart and we trust him. We look forward to his continued support.” |